LNF User Symposium – Sharing ideas and celebrating innovation

The symposium highlighted the world-class work done at the University.

Enlarge

Enlarge

The 2016 Lurie Nanofabrication Facility (LNF) User Symposium highlighted the cutting-edge research enabled by Michigan’s world-class facility. The Symposium included technical talks, a poster session, and the opportunity for discussion and networking. Attendees represented many departments throughout the University, as well as industrial users of the LNF. The event was sponsored by Angstrom Engineering, Bruker, Hitachi, and Kurt J. Lesker Company.

Mark Kushner, George I. Haddad Professor of Electrical Engineering and Computer Science, presented the event’s keynote address,“The Role of Plasma Modeling in the Innovation Cycle for Nanofabrication.” In this talk, Prof. Kushner discussed the vital role plasma materials processing plays in the fabrication of devices from nano-scale transistors to MEMS lnfelerometers.

“Arguably,” says Kushner, “advances in these technologies might not have progressed beyond that of the 1990s in the absence of plasma enabled device fabrication.”

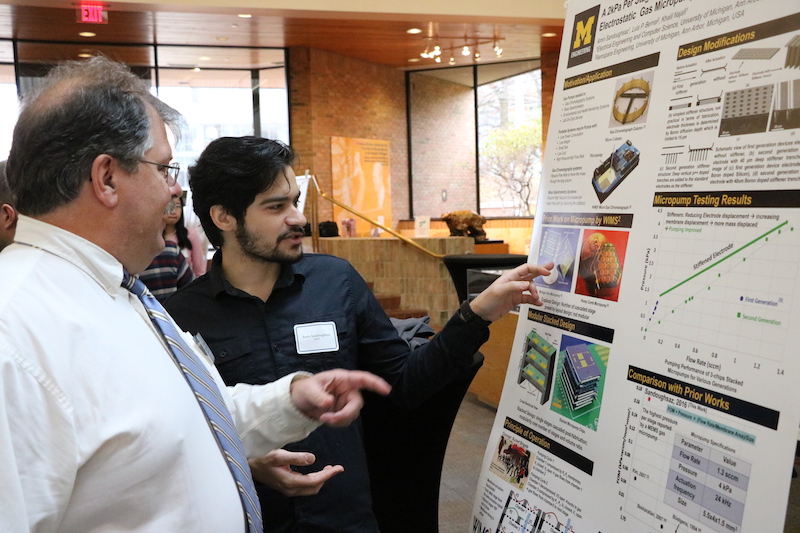

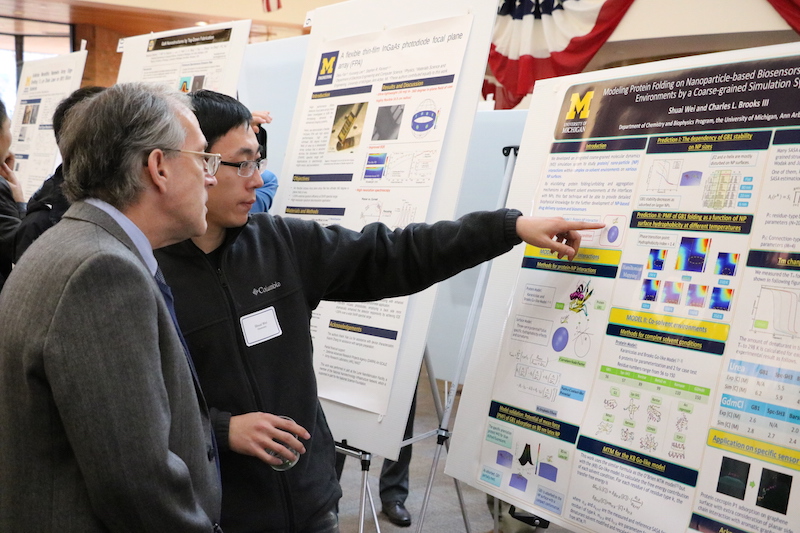

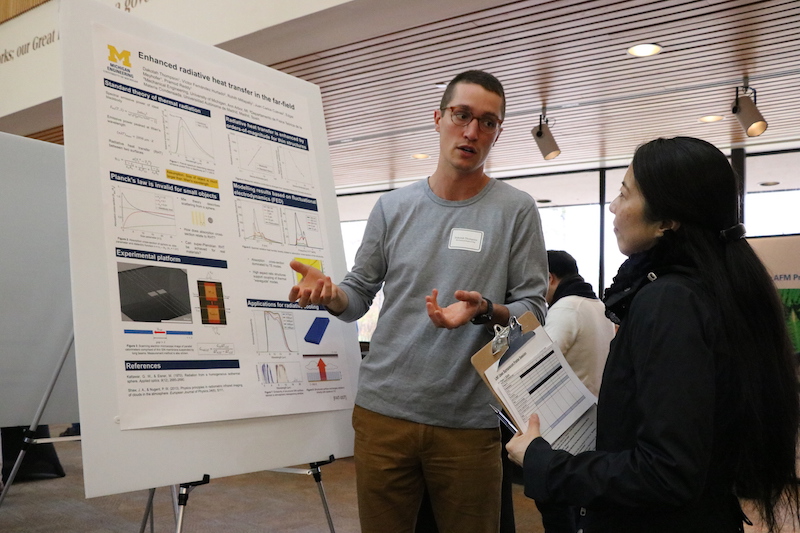

The symposium poster session presented the diverse work of graduate students who use the facility and rely on its capabilities to build next-generation devices. Four students were winners of this year’s LNF Users Symposium Poster Awards, all of whom are ECE graduate students:

1st prize: Tal Nagourney, 130 Second Ring-Down Time and 3.98 Million Quality Factor in 10 kHz Fused Silica Micro Birdbath Shell Resonator. Advisor: Prof. Khalil Najafi

Runner up: Brandon Demory,GaN Nanostructures by Top-Down Fabrication. Advisor: Prof. PC Ku

Runner up: Armin Jam,A Novel Sub-Millimeterwave Radar System for Autonomous Vehicle and Collision Avoidance Applications. Advisor: Prof. Kamal Sarabandi

Honorable mention: Kanghwan Kim,Monolithic integration of cell-sized LEDs on silicon neural probes. Advisor: Prof. Euisik Yoon

Enlarge

Enlarge

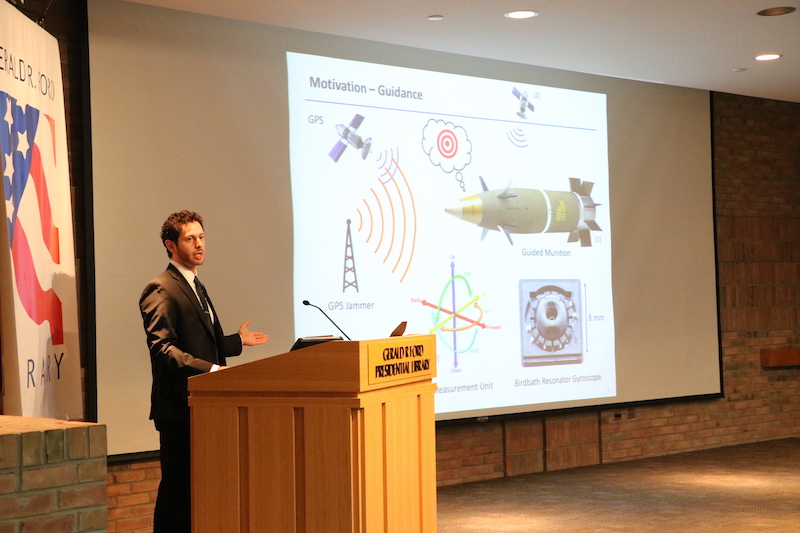

Several graduate students delivered technical presentations throughout the day. The following talks gave attendees a detailed look at current work in the LNF:

Microfluidics and Nanotechnology: Future of Cancer Research and Personalized Medicine

Prof. Sunitha Nagrath (U-M Chem. Eng.)

Mind the Gap: Extending Research Beyond Graduation Through Entrepreneurship

Dr. Thomas Daunais (Upland Nanotech)

High-Q Blown Glass Resonators for Gyroscopes

Tal Nagourney (U-M EECS)

Study of Bulk Resistivity of Topological Kondo Insulator SmB6 and its Alloys Below the Bulk-to-Surface Crossover Temperature Using Non-local Corbino Transport

Yun Suk Eo (U-M Physics)

Advanced Nanofabrication Technologies of Processing Layered Semiconductors for New Device Applications

Mikai Chen (U-M ME)

Metasurface Generation of Accelerating Light

Meredith Henstridge (U-M Physics)

Silicon Nitride Parabolic Lenses for Enhanced Light Extraction From GaN Nanostructures

Brandon Demory (U-M EECS)

Photos from the Event

Download these photos on Flickr

About the LNF

The Lurie Nanofabrication Facility is a state-of-the-art cleanroom facility for research on micro- and nanotechnology. The LNF is available for use by government, industry, and university research groups. Equipment and processes are available for research on silicon integrated circuits, MEMS, III-V compound devices, organic devices and nanoimprint technology. The facility also is available for researchers from non-traditional disciplines to make use of our processes, such as metal and dielectric coatings, vacuum processes, fabrication of micro and nano components and metrology tools.

The LNF represents an expansion from 6,500 to more than 12,500 square feet of state-of-the-art class 10/100/1000 and 10,000 cleanroom facilities. The original facility opened in September 1986 and was fully operational by 1988. The total investment in the newly named Robert H. Lurie Nanofabrication Facility, combining the existing facility, the latest addition and equipment, exceeds $100M.

MENU

MENU